Eaton Metal Works

The Eaton Metal Works began business in 1903 in Omaha as a subsidiary of Eaton Metal Products. It served as a metal fabrication facility for the national company. Eaton Metal Works initially focused on producing water and grain tanks to be used in the cultivation of agriculture. This focus was expanded upon as order volume overwhelmed manufacturing capabilities in 1913 (EMP, 2013). Given this success, Eaton Metal Works began expanding into all types of metalworking, ranging from creating pens, knives, and cutlery, to fitting pipes. There is not a well-documented transition explaining Eaton Metal Product’s divestment of focus on agricultural products in favor of general goods, but our team speculates this was a directive from corporate offices.

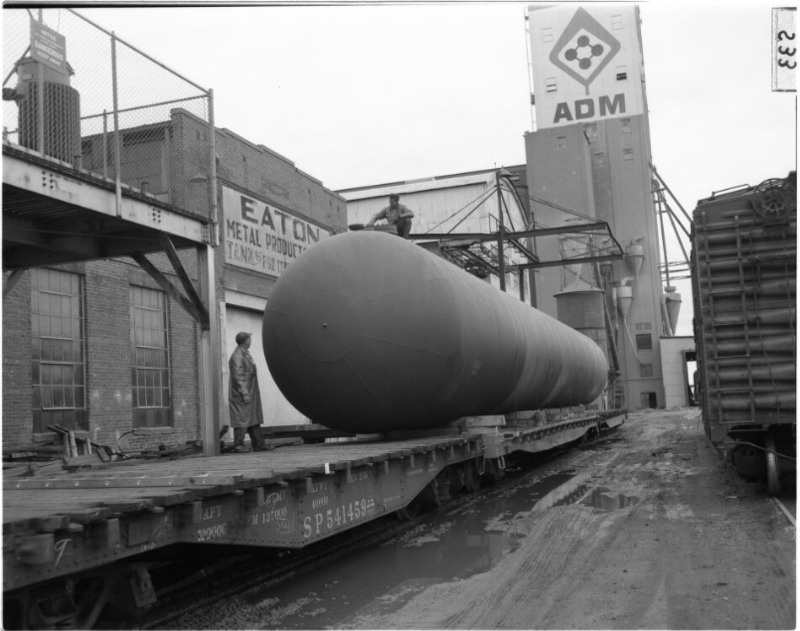

The Omaha location suffered relative stagnation compared to other more Western locations throughout the early 1940s. The United States Navy offered certain divisions of Eaton Metal Products lucrative contracts to assist in the American war effort in WWII (EMP, 2013), which the Omaha location did not receive. Less than a decade after the war concluded Eaton Metal Works was purchased and absorbed by Puritan Manufacturing Incorporated in 1958, ending the company’s semi-successful and semi-autonomous run. The decision to purchase Eaton Metal Works was justified by the massive size of the facility Eaton had built (PMI, 2021). Puritan Manufacturing has not closed the business that once was Eaton Metal Works, nor demolished the original structure of the factory. Eaton Metal Works was located on 24th and South Grant St, directly within the boundaries of the Omaha Lead Superfund Site.

Eaton Metal Works contributed to the history of industrial lead in Omaha through coating metal products with lead paint. Considering Eaton's massive success in selling products used in agricultural settings (EMP, 2013) the ability for lead particulates to be ingested is potentially higher than other products undergoing similar processes (EMP, 2013). Lead paint wears over time while exposed to natural elements, which could result in lead particulates shedding off Eaton products in agricultural settings. Lead particulates shed from the eroding lead-based paint on grain silos could permeate the soil and contaminate farmland or could unknowingly contaminate the entire contents of a full silo. Disastrous effects could occur if lead particulates enter still-water reserves, such as poisoning wildlife or destroying crops via contaminated water (Cheung et al, 2017).

Eaton products once again encapsulate historian Leif Fredrickson’s argument that the prevalence of lead is directly linked to its inexpensive way to improve existing technologies (Fredrickson, 2017). Eaton Metal Works reveals the naivete of assuming that 1. technology that makes our lives easier and 2. decisions that result in harm result from malice rather than ignorance. Eaton Metal Works operated before any widespread community backlash against industrial lead, allowing its previous mistakes to go relatively unnoticed. Even Puritan Manufacturing does not disclose Eaton Metal Works’ documented history of using lead-based paint on its website or history page which is impressively thorough (PMI, 2021). This omission of Eaton Metal Works’ history may be a strategic business decision on behalf of Puritan Manufacturing, but it may also reflect a general historical amnesia about the pervasiveness of industrial risk in society at large. This exact sentiment is the thesis of the work Sights Unseen, a book that underscores the dangers outdated infrastructure and housing unknowingly poses to civilians. It was not clear when Eaton Metal Works stopped coating their products with lead-based paint.