Omaha Steel Works

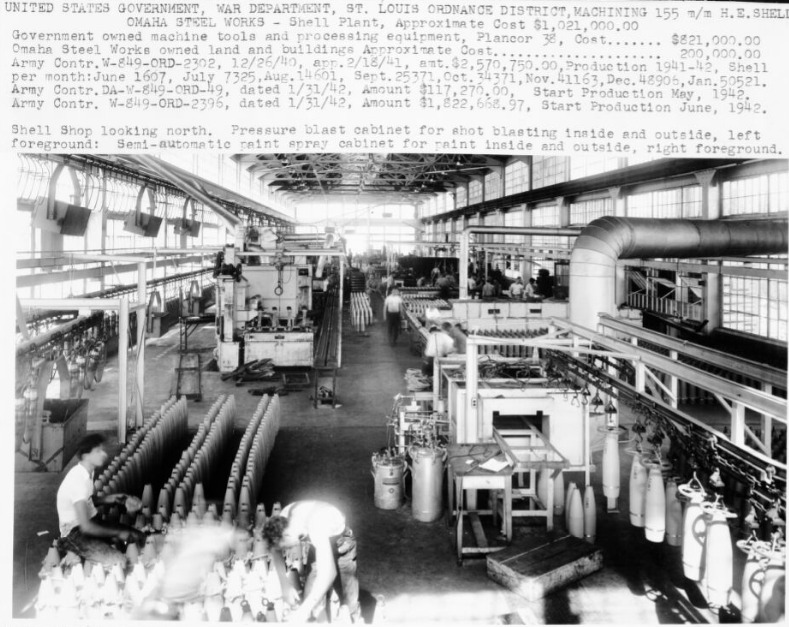

Omaha Steel Works was founded in 1906 by John W Towle and Fred K Smith to be a foundry for smelting and handling industrial lead (OS, 2021). The company had humble beginnings until receiving a contract to provide steel for the State Capitol Building in Lincoln Nebraska in 1922 (OS, 2021). This project gave Omaha Steel Works a sense of corporate direction, and in the 1930s, Omaha Steel Works began producing steel castings of locomotive engines and specialty components. During WWII, Omaha Steel Works was commissioned to build military landing craft tanks and artillery shells for the United States Navy (OS, 2021). In the 1950s, Omaha Steel Works rebranded itself as OmSteel and invested in a number of subsidiaries, such as a real estate holding company and a separate structural steel manufacturer. The 1970s brought with it another name change to Omaha Steel Casings Company, which is the current name of the company. Expansions into specialty metal fitting fields and investments in digital technologies are current priorities of the company (OS, 2021).

Despite many fluctuations to the size and nature of this foundry, one element remained constant: the usage of lead paint to coat metal products. Much like other members of the industry, Omaha Steel Works applied lead-based paints to their metal products to increase durability and mitigate corrosion damage. This process proved to be ineffective as lead paint degrades in extreme elements rendering it partially successful at protecting machinery (OS, 2021). Metal items produced at this foundry posed serious health risks to humans regarding exposure to lead, caused by particulates of industrial lead being aerosolized as lead-based paint degrading. Workers at the Omaha Steel Works would have been exposed to industrial lead during the coating process and while handling painted metal products (Fletcher, 2019). Civilians were exposed to industrial lead through air pollution both caused by the early smelting activities of the foundry, and until the 1970s by interacting with products coated in lead-based paint. Remediation efforts to remove lead-based paint from homes offered no protection or help for consumers of Omaha Steel Works products. EPA efforts were focused on soil remediation, so the cleaning of consumer goods with lead paint was not a priority of the Federal government.

Products from the Omaha Steel Works had a unique ability to permeate all areas of Omaha due to several business partnerships between Omaha Steel Works and elite-level projects sponsored by State policies. Omaha Steel Works directly benefitted from the State and Federal government contracts it received, allowing it to remain competitive with other more established foundries. Omaha Steel Works saw particularly strong corporate growth while manufacturing vehicles and supplies for the Allied war effort during 1941-1945, and subsequently had to expand to meet the increase in demands on the foundry (Fletcher, 2019). It is unclear how long military vehicles produced at the Omaha Steel Works were in service for; often records with sensitive data are classified to prevent domestic espionage. Data from a group of local researchers provided a rudimentary list cataloging thirty one separate military vehicles produced between 1942-1944 (Colton, 2015). If coated with lead paint, these vehicles potentially exposed American soldiers to industrial lead both domestically and abroad. Military vehicles are especially susceptible to wear, and the maintenance involved in repainting or operating machinery in poorly ventilated conditions are concerning. There are no records confirming the decommissioning of vehicles painted by Omaha Metal Works, nor the final location of these vehicles. Our team speculated that the increasingly-large military presence in Omaha following WWII would potentially allow for Omaha Steel Works painted vehicles to remain within the State of Nebraska. Existing records for military equipment request contracts show that products for the armed forces routinely came from industries in Omaha, some of which used industrial lead (Colton, 2015).