Beef Packing Crate

Title

Beef Packing Crate

Subject

Swift’s Premium beef shipping crate represents the local and global meat trade of the past. Both packed by an American company and a “Product of Argentina”, this crate shows how large the meat market was. Refrigerated railcars and ships played a huge role in transforming food into a global agro-industry. Countries around the world engaged in a meat trade with the United States, and it was itself one of the largest exporters of beef. Into the mid-twentieth century, Omaha, with its stockyards and meat packing plants, was a central node in this system. The meat trade had changed shipping and agricultural technologies, economies, and international markets. These impacts were far greater than the environmental cost of eating an eight ounce steak. It enabled Western diets that privilege meat consumption and affect both the environment and humans. The start of the Anthropocene may not have been due to exportation of meat, yet the meat industry played and continues to play a significant role in Earth System change.

Description

The composition of the Swift’s Premium beef shipping crate is simplistic, but its history in relation to the meatpacking industry, Omaha, and the Anthropocene was complex. The crate in The Durham Museum collection consists of wooden planks held together by nails. Emblazoned on the front of the box are “Brisket Beef” and a “Swift’s Premium” logo. The writing on the side of the box indicates its origin. It was a “Product of Argentina” and the beef it contained was “Packaged for Swift and Company - Chicago, Illinois.” (Figure I) The early 20th century was likely the period of the crate’s production based on similar “corned beef shipping crates” in other museum collections (National Museum of American History, n.d.). This shipping crate was a simple box, but the transportation systems it took advantage of allowed consumers to eat distant environments.

During the Second Industrial Revolution of the early nineteenth century, the United States became more urbanized, which increased the demand for fresh meat shipped longer distances (K. Lerner and B. Lerner 2014, 3703). During the mid-nineteenth century, the meatpacking industry had limited methods to prevent meat spoilage, which restricted its operation primarily to the cold winter months (Grant 2003, 365). As a result, most Americans had limited access to fresh meat.

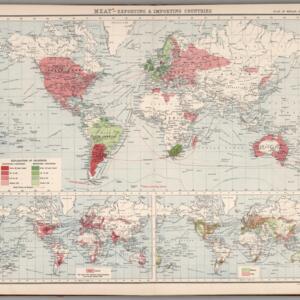

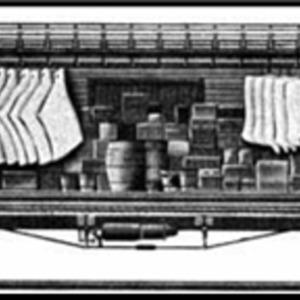

The invention of refrigeration in railcars and ships in the late nineteenth century revolutionized the meatpacking industry and redirected the trajectory of the country. Gustavus F. Swift, founder of Swift and Company, designed and implemented the refrigerated railcar. Day and night, through hot and cold weather, these “ice boxes traveling on wheels” shipped meat across the country and abroad (Swift and Company 1920, 67-68). The French scientist and engineer Charles Tellier was the “first to apply refrigeration successfully to the shipment of meat across the tropics” (Jones 1929, 160). Refrigerated ships established a system of fresh meat exchange between countries near and far. At the beginning of the twentieth century, the major contributors in the meat trade shifted from Europe and North America to South America and Australasia because of “increasing pressure of population on means of subsistence” (Jones 1929, 164).

Prior to this shift, the United States had supplied beef to numerous countries around the world. (Figure III) However, a decline in the amount of beef exported from the United States was inevitable. In the first decade of the twentieth century, the population of the United States increased by 21% while the consumption of beef remained constant (Jones 1929, 164). The United States had to rely on other countries as a source of beef, as a result. In 1907, Swift and Company purchased the La Plata Cold Storage Company in Argentina. According to historian first name Jones, this marked “the entry of American meat packers into the Argentine meat industry” (Jones 1929, 168).

American reliance on cattle from Argentina displaced the ecological pressure of their consumption to Argentina’s environment. The plains of Argentina originally extended for miles with hardly a tree or bush to vary the monotone of green grasslands (Tower 1918, 293). The construction of railroads and implementation of arable farming in Argentina changed the composition of the land. The increasing population within Argentina and the external pressure to supply countries like the United States stimulated these changes. Railroads were more convenient to access ports than land travel, yet they consumed a large portion of Argentina plains (Tower 1918, 300-301). In Argentina, cattle no longer grazed freely on native grasses. The cattle consumed crops like corn and alfalfa in fenced pastures (Tower 1918, 311). As a result, the quality of cattle improved, but crops started to overtake the acres of prairie.

In the United States, another influential transition took place during the nineteenth century. The midwestern livestock industry evolved from small, independent producers to an agroindustry driven by packers like Swift and Company. Prior to the mid-1860s, butchers did their own slaughtering, and people would go to the local butcher to get their meat (Swift and Company 1920, 3). Early builders of the packing industry like Gustavus F. Swift thought a more efficient method of meat packing and distribution was necessary with the growth of population and industry in America (Swift and Company 1920, 4). The demand for a steady supply of meat that was higher quality and lower priced catalyzed the shift from butchers to meatpacking plants in Chicago.

The innovative thinking of one man ultimately led to the establishment of a well-known packing company and a means of transportation that would forever change the meatpacking industry. Gustavus F. Swift started as a butcher for his brother’s business but was eager to get out into the world and make something of himself. Swift entered the meatpacking industry at age sixteen when he began his own “meat-market business” (Grant 2003, 366). From the start, Swift wanted to serve his customers and ensure the quality of his product which contributed to his success in the meatpacking industry (Swift and Company 1920, 14). In 1875, Swift moved to Chicago and implemented his own slaughterhouse. During this time, meat packing was a seasonal industry and there was no distribution system in place to ship fresh meat to markets.

After the railroads refused to build refrigerated railcars, Swift took the problem into his own hands. Swift and his engineer, Andrew Chase, implemented the first successful refrigerated railcar in 1877. This efficient design allowed warm air to exit through the floor and cold air to circulate down from ice stored in the ceiling (K. Lerner and B. Lerner 2014, 3704).

Following the invention of the refrigerated railcar, “Swift saw his company grow into one of the nation’s main meatpacking companies, with a reach throughout the United States. By 1900, it had also reached beyond national boundaries” (Grant 2003, 365). To satisfy a range of customers, Swift and Company offered a variety of products other than beef such as “hams, sausage, bacon, chickens, eggs, butter, lard, shortening, oleomargarine, bouillon cubes, and various soaps'' (Grant 2003, 365). Despite the fluctuations in production and price, Swift and Company remained a large operation into the middle of the nineteenth century.

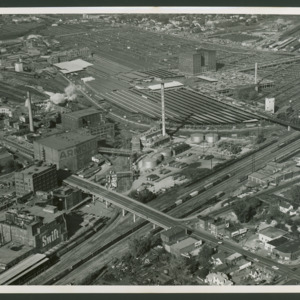

Nebraska underwent significant growth and became a dominant cattle and grain producing state in the 1880s. Stockyard towns started to emerge during this period. The introduction of stockyards into Omaha helped flourish the area and its economy (Larsen et al. 2007, 109-118). The history of the Omaha Stockyards dates to 1882, when a Wyoming rancher named Alexander Swan devised a stockyard scheme in Omaha (Larsen et al. 2007, 112). In 1883, William Paxton, John McShane, Peter Iler, John Creighton, Thomas Swobe, Frank Murphy, and Alexander Swan saw a market and created the Union Stock Yards Company (Fine 1956). Omaha was in the center of the country along the natural route from the west to the east. The area also had abundant resources such as water and crops to feed livestock. Altogether, Omaha’s location and resources attributed to its success and legacy in the meat industry (Larsen and Cottrell 1982, 74-75).

The introduction of refrigeration into railcars and ships during the nineteenth century globalized the meat industry and allowed for packing companies like Swift to flourish. Refrigerated railcars or “traveling ice boxes” allowed the distribution of fresh meat to locations near and far without spoilage. Refrigerated railcars transformed the economy and provided a more efficient way to transport cattle. Ranchers shipped cattle by rail from Texas to Chicago, Illinois in the mid-1800s. After the cattle arrived, it was more profitable to slaughter them in Chicago and ship the carcasses east rather than send live cattle east by rail (K. Lerner and B. Lerner 2014, 3703). However, to build railroads deforestation had to occur, and factories produced the materials to build railroads. This shows how one method of transportation can greatly impact the environment. On the other hand, refrigerated ships allowed countries to import and export products from distal environments without perishing: “How successfully the ship and her refrigeration and the engineers in charge co-operate is shown by the fact that so large a part of the nation’s perishable food supplies is regularly brought to these shores in good condition, after passing through the vicissitudes of temperature encountered on the long ocean voyage” (American Society of Refrigerating Engineers 1915, 68). In the late nineteenth century, countries around the world engaged in a meat trade which resulted in exploitation and environmental change.

The history of the beef trade in Argentina dates back Spanish settlement in the sixteenth century. The cattle originally dominated the landscape to the point where dogs had to limit the number of calves that successfully grew to adulthood. Despite the plentiful numbers of cattle throughout the Argentine republic, there was a lack of commerce related industry on their east Atlantic coast in the 1700's (Jones 1929, 156-157). There was a demand for meat in the United States, giving Argentina a way of exporting such large quantities of cattle. This demand did not last long, forcing the slaughter of many farm animals. In 1875, there was almost no demand for international meat (Jones 1929, 158). It was not until the use of refrigeration that Argentina became solidified in the world of meat export.

La Plata Cold Storage Company, Ltd. was one of the biggest packing houses of its time and for a meat processing property, it was extremely sanitary. People from Europe and North America would tour the pristine establishment (The La Plata Cold Storage Company, 1913). Swift and Company later bought La Plata Cold Storage Company, Ltd. Shortly after this purchase, Swift retired from the company, but it continued into the meat trade with the help of refrigerated meat. Argentina continued to rise as a powerful seller of beef, shown by a remarkable 2,989,805 beef quarters exported in 1913. These numbers surpassed the United States, marking the decline of meat export in the states (Melvin 1914, 382). Even though Argentina's main frozen and chilled beef market was in England, our brisket box from Swift and Company is proof that the South American country shipped all around the world. From October of 1913 to September of 1914, Argentina shipped around 140,000,000 pounds of beef into the United States. With the addition of other types of meat, the total was over 150,000,000 pounds (Melvin 1914, 388). America was slowly becoming more of an importer than an exporter at this time in history so Argentine enterprises had to respond with more exports (The La Plata Cold Storage Company 1913).

Argentine meat production impacted local environments, especially land used for grazing. Around 1913, farmers shifted to alfalfa as a primary feedstock. This drought tolerant plant eased the worried minds of many estancieros (cattle farmers) who worried about grazing pressure (Melvin 1914, 385). Drought was a perennial challenge on the Pampa, the climate of which was like that of subtropical areas (Tower 1918, 305). This climate would include warmer temperatures with great humidity for the alfalfa plant. The profit associated with the cattle trade diminished the amount of crops grown due to the large income and easier nature of transporting cattle than crops (Tower 1918, 310). As alfalfa dominated the region, fewer cattle ate corn. Not only did the use of alfalfa help profit increase, but it also helped the environment. With the help of symbiotic fungi, alfalfa fixes nitrogen, enabling it to fertilize the landscape (Yost 2021).

The purchase of La Plata Cold storage company by Swift and Company in 1917 began the trade war between American and British companies investing in the Argentine meat trade. The 1924 opening of Swift and Company's Rosario plant in the town Villa Gobernador Galvez, marked the company's astounding seventy percent control of the meat exportation market (JBS-Swift Argentina S. A. 2022). Despite this dominance, Argentine companies fell below 20% of total trade, meanwhile the United States produced around 50% of the meat (Jones 1929, 171). L. D. H. Weld, a manager in the Commercial Research Department of Swift and company wrote "Since 1900, Argentina and Australia have been gradually taking our place in foreign markets because they could produce beef and mutton more cheaply than we could" (Weld 1918, 168).

In 1917, the company found an increased need for meat and the farmers provided increasingly more livestock. Not only were the citizens of the United States hungry for meat, but the soldiers and allies fighting in the "European War" or WWI. The installation of Meatless days was a way of spending time to ship meat to those fighting in the war. This export of frozen meat to the allies created a much smaller supply in the states.

Another wave of modernized transportation further transformed the industry. Trucking became more prevalent in the twentieth century, and trucks moved boxed beef from packing houses to local stores. Omaha was a pioneer of this transition, which "further enhanced Omaha's position as transportation hub" (Larsen and Cottrell 1982, 249). By 1955, Omaha had taken over as the leading meat producer in the nation according to the USDA (United States Department of Agriculture). In 1916, 70% of the amount of meat produced in Omaha was for the United States. This number dropped to around 60% in 1929. Swift and others bought around sixty-five other meat plants in 1927 to raise these numbers back up (Wood 2020, 277).

In the late 1960s, three big corporations in this industry began to leave Omaha. Cudahy, Armour, and lastly Swift took their business elsewhere. More than ten thousand jobs and roughly $500 million flowed out of the economy (Larsen 2007, 339). Swift and Company shutdown a majority of its plants "partly because for a while it got out of the beef business and partly because the meat industry no longer had to depend on railroads for shipping its products" (Grant 2003, 365). Subsequently, Swift and Company underwent a series of changes in ownership and name. By 1985, Charles Hillinger wrote in the Los Angeles Times that "although the city stockyards are merely a shadow of what they used to be, Omaha remains the capital of America's meat industry" (Hillinger 1985). Omaha continues to be a dominating force in the industry, exemplified by Omaha Steaks International Inc. This company does not use wooden boxes like Swift and Company's brisket package, but they do still sell packaged frozen meat. Currently meat often comes in styrofoam boxes with the use of liquid nitrogen to maintain such cold temperatures and preserve the product. The meat trade in general has decreased with the growing movement towards meatless diets.

The shipping box that once contained brisket shows the complexity of using a single object to symbolize the Anthropocene. Changes in this trade incentivized new cropping strategies, which improved some environmental aspects. For instance, the use of alfalfa is much better for the soil and environment than corn. When planted for profit however, we see the ecological costs that outweigh these small benefits. Long supply chains fueled by non-Western environments and people created a demand for meat in the West. It seems inconceivable that one might have to go all the way to Argentina for something as simple as a burger patty, yet it is precisely this system that affords cheap calories. The Western diet that is "rich in animal proteins, processed grains, and sugar" has provided sustenance at a cheaper level thanks to big corporations like Swift and Company (Otter 2020, 2). Transportation used to provide this more accessible diet, changes in farming, and ecological impacts have all helped shape the world we live in today; a world where the cost of making an eight-ounce steak is far greater than we realize. Like the meat industry, this world is rapidly changing and adapting to our needs. It is truly incredible how something as simple as a box of wood and nails can shape our world in the past, present, and future.

During the Second Industrial Revolution of the early nineteenth century, the United States became more urbanized, which increased the demand for fresh meat shipped longer distances (K. Lerner and B. Lerner 2014, 3703). During the mid-nineteenth century, the meatpacking industry had limited methods to prevent meat spoilage, which restricted its operation primarily to the cold winter months (Grant 2003, 365). As a result, most Americans had limited access to fresh meat.

The invention of refrigeration in railcars and ships in the late nineteenth century revolutionized the meatpacking industry and redirected the trajectory of the country. Gustavus F. Swift, founder of Swift and Company, designed and implemented the refrigerated railcar. Day and night, through hot and cold weather, these “ice boxes traveling on wheels” shipped meat across the country and abroad (Swift and Company 1920, 67-68). The French scientist and engineer Charles Tellier was the “first to apply refrigeration successfully to the shipment of meat across the tropics” (Jones 1929, 160). Refrigerated ships established a system of fresh meat exchange between countries near and far. At the beginning of the twentieth century, the major contributors in the meat trade shifted from Europe and North America to South America and Australasia because of “increasing pressure of population on means of subsistence” (Jones 1929, 164).

Prior to this shift, the United States had supplied beef to numerous countries around the world. (Figure III) However, a decline in the amount of beef exported from the United States was inevitable. In the first decade of the twentieth century, the population of the United States increased by 21% while the consumption of beef remained constant (Jones 1929, 164). The United States had to rely on other countries as a source of beef, as a result. In 1907, Swift and Company purchased the La Plata Cold Storage Company in Argentina. According to historian first name Jones, this marked “the entry of American meat packers into the Argentine meat industry” (Jones 1929, 168).

American reliance on cattle from Argentina displaced the ecological pressure of their consumption to Argentina’s environment. The plains of Argentina originally extended for miles with hardly a tree or bush to vary the monotone of green grasslands (Tower 1918, 293). The construction of railroads and implementation of arable farming in Argentina changed the composition of the land. The increasing population within Argentina and the external pressure to supply countries like the United States stimulated these changes. Railroads were more convenient to access ports than land travel, yet they consumed a large portion of Argentina plains (Tower 1918, 300-301). In Argentina, cattle no longer grazed freely on native grasses. The cattle consumed crops like corn and alfalfa in fenced pastures (Tower 1918, 311). As a result, the quality of cattle improved, but crops started to overtake the acres of prairie.

In the United States, another influential transition took place during the nineteenth century. The midwestern livestock industry evolved from small, independent producers to an agroindustry driven by packers like Swift and Company. Prior to the mid-1860s, butchers did their own slaughtering, and people would go to the local butcher to get their meat (Swift and Company 1920, 3). Early builders of the packing industry like Gustavus F. Swift thought a more efficient method of meat packing and distribution was necessary with the growth of population and industry in America (Swift and Company 1920, 4). The demand for a steady supply of meat that was higher quality and lower priced catalyzed the shift from butchers to meatpacking plants in Chicago.

The innovative thinking of one man ultimately led to the establishment of a well-known packing company and a means of transportation that would forever change the meatpacking industry. Gustavus F. Swift started as a butcher for his brother’s business but was eager to get out into the world and make something of himself. Swift entered the meatpacking industry at age sixteen when he began his own “meat-market business” (Grant 2003, 366). From the start, Swift wanted to serve his customers and ensure the quality of his product which contributed to his success in the meatpacking industry (Swift and Company 1920, 14). In 1875, Swift moved to Chicago and implemented his own slaughterhouse. During this time, meat packing was a seasonal industry and there was no distribution system in place to ship fresh meat to markets.

After the railroads refused to build refrigerated railcars, Swift took the problem into his own hands. Swift and his engineer, Andrew Chase, implemented the first successful refrigerated railcar in 1877. This efficient design allowed warm air to exit through the floor and cold air to circulate down from ice stored in the ceiling (K. Lerner and B. Lerner 2014, 3704).

Following the invention of the refrigerated railcar, “Swift saw his company grow into one of the nation’s main meatpacking companies, with a reach throughout the United States. By 1900, it had also reached beyond national boundaries” (Grant 2003, 365). To satisfy a range of customers, Swift and Company offered a variety of products other than beef such as “hams, sausage, bacon, chickens, eggs, butter, lard, shortening, oleomargarine, bouillon cubes, and various soaps'' (Grant 2003, 365). Despite the fluctuations in production and price, Swift and Company remained a large operation into the middle of the nineteenth century.

Nebraska underwent significant growth and became a dominant cattle and grain producing state in the 1880s. Stockyard towns started to emerge during this period. The introduction of stockyards into Omaha helped flourish the area and its economy (Larsen et al. 2007, 109-118). The history of the Omaha Stockyards dates to 1882, when a Wyoming rancher named Alexander Swan devised a stockyard scheme in Omaha (Larsen et al. 2007, 112). In 1883, William Paxton, John McShane, Peter Iler, John Creighton, Thomas Swobe, Frank Murphy, and Alexander Swan saw a market and created the Union Stock Yards Company (Fine 1956). Omaha was in the center of the country along the natural route from the west to the east. The area also had abundant resources such as water and crops to feed livestock. Altogether, Omaha’s location and resources attributed to its success and legacy in the meat industry (Larsen and Cottrell 1982, 74-75).

The introduction of refrigeration into railcars and ships during the nineteenth century globalized the meat industry and allowed for packing companies like Swift to flourish. Refrigerated railcars or “traveling ice boxes” allowed the distribution of fresh meat to locations near and far without spoilage. Refrigerated railcars transformed the economy and provided a more efficient way to transport cattle. Ranchers shipped cattle by rail from Texas to Chicago, Illinois in the mid-1800s. After the cattle arrived, it was more profitable to slaughter them in Chicago and ship the carcasses east rather than send live cattle east by rail (K. Lerner and B. Lerner 2014, 3703). However, to build railroads deforestation had to occur, and factories produced the materials to build railroads. This shows how one method of transportation can greatly impact the environment. On the other hand, refrigerated ships allowed countries to import and export products from distal environments without perishing: “How successfully the ship and her refrigeration and the engineers in charge co-operate is shown by the fact that so large a part of the nation’s perishable food supplies is regularly brought to these shores in good condition, after passing through the vicissitudes of temperature encountered on the long ocean voyage” (American Society of Refrigerating Engineers 1915, 68). In the late nineteenth century, countries around the world engaged in a meat trade which resulted in exploitation and environmental change.

The history of the beef trade in Argentina dates back Spanish settlement in the sixteenth century. The cattle originally dominated the landscape to the point where dogs had to limit the number of calves that successfully grew to adulthood. Despite the plentiful numbers of cattle throughout the Argentine republic, there was a lack of commerce related industry on their east Atlantic coast in the 1700's (Jones 1929, 156-157). There was a demand for meat in the United States, giving Argentina a way of exporting such large quantities of cattle. This demand did not last long, forcing the slaughter of many farm animals. In 1875, there was almost no demand for international meat (Jones 1929, 158). It was not until the use of refrigeration that Argentina became solidified in the world of meat export.

La Plata Cold Storage Company, Ltd. was one of the biggest packing houses of its time and for a meat processing property, it was extremely sanitary. People from Europe and North America would tour the pristine establishment (The La Plata Cold Storage Company, 1913). Swift and Company later bought La Plata Cold Storage Company, Ltd. Shortly after this purchase, Swift retired from the company, but it continued into the meat trade with the help of refrigerated meat. Argentina continued to rise as a powerful seller of beef, shown by a remarkable 2,989,805 beef quarters exported in 1913. These numbers surpassed the United States, marking the decline of meat export in the states (Melvin 1914, 382). Even though Argentina's main frozen and chilled beef market was in England, our brisket box from Swift and Company is proof that the South American country shipped all around the world. From October of 1913 to September of 1914, Argentina shipped around 140,000,000 pounds of beef into the United States. With the addition of other types of meat, the total was over 150,000,000 pounds (Melvin 1914, 388). America was slowly becoming more of an importer than an exporter at this time in history so Argentine enterprises had to respond with more exports (The La Plata Cold Storage Company 1913).

Argentine meat production impacted local environments, especially land used for grazing. Around 1913, farmers shifted to alfalfa as a primary feedstock. This drought tolerant plant eased the worried minds of many estancieros (cattle farmers) who worried about grazing pressure (Melvin 1914, 385). Drought was a perennial challenge on the Pampa, the climate of which was like that of subtropical areas (Tower 1918, 305). This climate would include warmer temperatures with great humidity for the alfalfa plant. The profit associated with the cattle trade diminished the amount of crops grown due to the large income and easier nature of transporting cattle than crops (Tower 1918, 310). As alfalfa dominated the region, fewer cattle ate corn. Not only did the use of alfalfa help profit increase, but it also helped the environment. With the help of symbiotic fungi, alfalfa fixes nitrogen, enabling it to fertilize the landscape (Yost 2021).

The purchase of La Plata Cold storage company by Swift and Company in 1917 began the trade war between American and British companies investing in the Argentine meat trade. The 1924 opening of Swift and Company's Rosario plant in the town Villa Gobernador Galvez, marked the company's astounding seventy percent control of the meat exportation market (JBS-Swift Argentina S. A. 2022). Despite this dominance, Argentine companies fell below 20% of total trade, meanwhile the United States produced around 50% of the meat (Jones 1929, 171). L. D. H. Weld, a manager in the Commercial Research Department of Swift and company wrote "Since 1900, Argentina and Australia have been gradually taking our place in foreign markets because they could produce beef and mutton more cheaply than we could" (Weld 1918, 168).

In 1917, the company found an increased need for meat and the farmers provided increasingly more livestock. Not only were the citizens of the United States hungry for meat, but the soldiers and allies fighting in the "European War" or WWI. The installation of Meatless days was a way of spending time to ship meat to those fighting in the war. This export of frozen meat to the allies created a much smaller supply in the states.

Another wave of modernized transportation further transformed the industry. Trucking became more prevalent in the twentieth century, and trucks moved boxed beef from packing houses to local stores. Omaha was a pioneer of this transition, which "further enhanced Omaha's position as transportation hub" (Larsen and Cottrell 1982, 249). By 1955, Omaha had taken over as the leading meat producer in the nation according to the USDA (United States Department of Agriculture). In 1916, 70% of the amount of meat produced in Omaha was for the United States. This number dropped to around 60% in 1929. Swift and others bought around sixty-five other meat plants in 1927 to raise these numbers back up (Wood 2020, 277).

In the late 1960s, three big corporations in this industry began to leave Omaha. Cudahy, Armour, and lastly Swift took their business elsewhere. More than ten thousand jobs and roughly $500 million flowed out of the economy (Larsen 2007, 339). Swift and Company shutdown a majority of its plants "partly because for a while it got out of the beef business and partly because the meat industry no longer had to depend on railroads for shipping its products" (Grant 2003, 365). Subsequently, Swift and Company underwent a series of changes in ownership and name. By 1985, Charles Hillinger wrote in the Los Angeles Times that "although the city stockyards are merely a shadow of what they used to be, Omaha remains the capital of America's meat industry" (Hillinger 1985). Omaha continues to be a dominating force in the industry, exemplified by Omaha Steaks International Inc. This company does not use wooden boxes like Swift and Company's brisket package, but they do still sell packaged frozen meat. Currently meat often comes in styrofoam boxes with the use of liquid nitrogen to maintain such cold temperatures and preserve the product. The meat trade in general has decreased with the growing movement towards meatless diets.

The shipping box that once contained brisket shows the complexity of using a single object to symbolize the Anthropocene. Changes in this trade incentivized new cropping strategies, which improved some environmental aspects. For instance, the use of alfalfa is much better for the soil and environment than corn. When planted for profit however, we see the ecological costs that outweigh these small benefits. Long supply chains fueled by non-Western environments and people created a demand for meat in the West. It seems inconceivable that one might have to go all the way to Argentina for something as simple as a burger patty, yet it is precisely this system that affords cheap calories. The Western diet that is "rich in animal proteins, processed grains, and sugar" has provided sustenance at a cheaper level thanks to big corporations like Swift and Company (Otter 2020, 2). Transportation used to provide this more accessible diet, changes in farming, and ecological impacts have all helped shape the world we live in today; a world where the cost of making an eight-ounce steak is far greater than we realize. Like the meat industry, this world is rapidly changing and adapting to our needs. It is truly incredible how something as simple as a box of wood and nails can shape our world in the past, present, and future.

Creator

Chaylea Mandina

Mark Wise

Mark Wise

Source

“Aerial View Omaha Stockyards.” Photograph. History Nebraska. Accessed October 29, 2022.

“Corned Beef Shipping Crate.” National Museum of American History. Accessed October 28, 2022.

Fine, Homer. “The Nation’s No. 1 Stockyards.” Nebraska Farmer, February 4, 1956.

Hillinger, Charles. “Where’s the Beef? Still in Omaha: Despite Pared-Down Volume, Stockyards Set National Trend.” Los Angeles Times, February 4, 1985.

“JBS-Swift Argentina S.A. (Argentina).” EMIS, October 2, 2022.

Jones, E. G. “The Argentine Refrigerated Meat Industry.” Economica, no. 26 (1929): 156–72.

Larsen, Lawrence H., and Barbara J. Cottrell. The Gate City A History of Omaha. Pruett Publishing Company, 1982.

Larsen, Lawrence H., Barbara J. Cottrell, Harl A. Dalstrom, and Kay Calamé Dalstrom. Upstream Metropolis: An Urban Biography of Omaha and Council Bluffs. University of Nebraska Press, 2007.

“Meat then and now.” Data Visualization. Columbia Evening Missourian, March 1, 1921.

Melvin, A.D. "Meat production in the Argentine and its effect upon the industry in the United States" National Agricultural Library Digital Collections, 1914, 381-390.

Otter, Chris. Diet for a Large Planet: Industrial Britain, Food Systems, and World Ecology. The University of Chicago Press, 2020.

“Refrigerated Railroad Car.” Digital Image. Industrial History, March 26, 2016.

"Refrigerated Trucks and Railway Cars." The Gale Encyclopedia of Science, 5th ed., edited by K. Lee Lerner and Brenda Wilmoth Lerner, 3703-3704. Vol. 7. Farmington Hills, MI: Gale, 2014.

"Swift & Company." International Directory of Company Histories, edited by Tina Grant, 364-367. Vol. 55. Detroit, MI: St. James Press, 2003.

Swift & Company. The Meat Packing Industry in America. Cornell University Library, 1920.

“Swift Packing Company Crate.” Photograph. The Durham Museum, September 10, 2022.

The American Society of Refrigerating Engineers. Refrigeration Engineering. University of Illinois Library, 1915.

“The La Plata Cold Storage Company.” The Sphere, July 1, 1913.

Tower, Walter S. “The Pampa of Argentina.” Geographical Review 5, no. 4 (1918): 293–315.

Weld, L. D. H. “The Live-Stock and Meat Situation.” The Annals of the American Academy of Political and Social Science 78 (1918): 168–75.

Wood, Charles L. “Beginning a Revolution: Markets, Packers, and Trucks, 1920-1940.” In The Kansas Beef Industry, 255–80. University Press of Kansas, 2020.

Yost, Matt. “Managing the Rotation from Alfalfa to Corn.” University of Minnesota Extension. Minnesota Agricultural Fertilizer Research and Education Council, 2021.

“Corned Beef Shipping Crate.” National Museum of American History. Accessed October 28, 2022.

Fine, Homer. “The Nation’s No. 1 Stockyards.” Nebraska Farmer, February 4, 1956.

Hillinger, Charles. “Where’s the Beef? Still in Omaha: Despite Pared-Down Volume, Stockyards Set National Trend.” Los Angeles Times, February 4, 1985.

“JBS-Swift Argentina S.A. (Argentina).” EMIS, October 2, 2022.

Jones, E. G. “The Argentine Refrigerated Meat Industry.” Economica, no. 26 (1929): 156–72.

Larsen, Lawrence H., and Barbara J. Cottrell. The Gate City A History of Omaha. Pruett Publishing Company, 1982.

Larsen, Lawrence H., Barbara J. Cottrell, Harl A. Dalstrom, and Kay Calamé Dalstrom. Upstream Metropolis: An Urban Biography of Omaha and Council Bluffs. University of Nebraska Press, 2007.

“Meat then and now.” Data Visualization. Columbia Evening Missourian, March 1, 1921.

Melvin, A.D. "Meat production in the Argentine and its effect upon the industry in the United States" National Agricultural Library Digital Collections, 1914, 381-390.

Otter, Chris. Diet for a Large Planet: Industrial Britain, Food Systems, and World Ecology. The University of Chicago Press, 2020.

“Refrigerated Railroad Car.” Digital Image. Industrial History, March 26, 2016.

"Refrigerated Trucks and Railway Cars." The Gale Encyclopedia of Science, 5th ed., edited by K. Lee Lerner and Brenda Wilmoth Lerner, 3703-3704. Vol. 7. Farmington Hills, MI: Gale, 2014.

"Swift & Company." International Directory of Company Histories, edited by Tina Grant, 364-367. Vol. 55. Detroit, MI: St. James Press, 2003.

Swift & Company. The Meat Packing Industry in America. Cornell University Library, 1920.

“Swift Packing Company Crate.” Photograph. The Durham Museum, September 10, 2022.

The American Society of Refrigerating Engineers. Refrigeration Engineering. University of Illinois Library, 1915.

“The La Plata Cold Storage Company.” The Sphere, July 1, 1913.

Tower, Walter S. “The Pampa of Argentina.” Geographical Review 5, no. 4 (1918): 293–315.

Weld, L. D. H. “The Live-Stock and Meat Situation.” The Annals of the American Academy of Political and Social Science 78 (1918): 168–75.

Wood, Charles L. “Beginning a Revolution: Markets, Packers, and Trucks, 1920-1940.” In The Kansas Beef Industry, 255–80. University Press of Kansas, 2020.

Yost, Matt. “Managing the Rotation from Alfalfa to Corn.” University of Minnesota Extension. Minnesota Agricultural Fertilizer Research and Education Council, 2021.

Rights

The Durham Museum Permanent Collection

Original Format

“Swift Packing Company Crate.” Photograph. The Durham Museum, September 10, 2022.

Collection

Citation

Chaylea Mandina

Mark Wise, “Beef Packing Crate,” Omaha in the Anthropocene, accessed July 27, 2024, https://steppingintothemap.com/anthropocene/items/show/42.

Embed

Copy the code below into your web page